QuNP

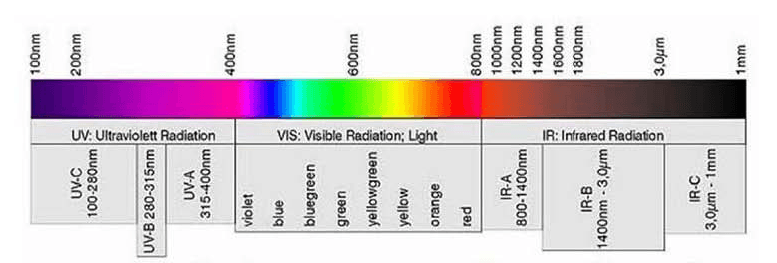

Quantum Nanophotonics LLC ( QuNP ) is currently developing new cutting edge advanced technology for a new generation of VIS - NIR - SWIR - MWIR - LWIR Photodetectors and Imaging Array Sensors based on Quantum NanoPhotonics.

The "Quantum NanoPhotonics" Advanced Product Innovation Design Center in our Irvine-CA HQ has secured several "Pending Patents" with USPTO and it is seeking active collaboration with Photonics Research Institutes and Industry Partners to engage in a Joint Venture for prototyping of next generation Photonics products and commercialization of its disruptive technology.

Contact us for more details and inquiries for your specific Advanced Photodetector product development needs.

Specializing in:

Custom High Reliability Photonics/Optoelectronic Product Development

Photodetector Sensors & Imaging PD Arrays (UV,Visible, NIR, SWIR)

Nanoporous-Si NIR Enhanced Detectors

Heterostructure Broadband VIS-NIR-SWIR-MWIR-LWIR Photodetetcors

Si PIN QUAD Fast Response NIR Detectors

Lateral and Dual Axis PSDs (Position Sensitive Diodes)

Radiation Hard Detectors (High Reliability & Space Applications)

X-Ray Detector Array Imaging (Medical & Security Applications)

SOI and Epi based UltraFast Detectors

Phototransistors

NPI (New Product Introduction) Commercialization:

- Raw Materials: High Resistivity FZ-Si, HP-Si

- Advanced Materials for NanoPhotonics

- Supply Chain support for Photonics R&D Prototyping:

- Photonics Processing Development

- Process Flow Integration

- Mask IC Design & GDSII

-Subcontracting Specialized Process Services:

Ion Implantation:

Dose Range: 1e11 to 1e16

Energy Range: 5KeV to 1MeV

PECVD Si3N4(Low Stress): 250Å-10,000Å

Sputtering Metallization: Most Metals&Alloys

E-Beam Metallization: Most Metals

Mask Making: Laser Direct Write

Turn Key Wafer Fab Foundries, Test & Assembly:

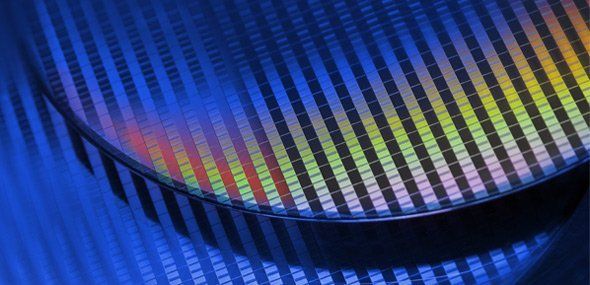

Si Wafer Fab Foundry

III-V Wafer Fab Foundry

NanoFabrication & MEMS

Wafer Test Facilities

Assembly Facilities

Analytical Service Facilities

Transfer to Pilot Line Manufacturing with Subcontracted Foundries

Process Flow Mapping

Yield Enhancements

Total Quality Management evaluation, 6s, FMEA, PFMEA, CA, CI

Lean Manufacturing 6s-Plus

Technology Capability Evaluation

Process Equipment Technology Evaluation & Selection

IP Evaluation

Value Chain Management

Executive Business Management support for Small Business / Start-Ups

Technical Support with Business Acquisition/Divestiture transition